What Size Torsion Spring For 16x7 Garage Door

How to Mensurate and Society Your Replacement Torsion Springs

Posted on December v, 2018 by IDC Spring

Updated January 29, 2021

Providing the correct torsion or extension spring for your application is our number one priority. From standard springs to hard-to-find replacement springs, IDC Spring promises the right spring for your application. Let us match your requirements to the correct IDC Spring solution. The guidelines beneath help identify the correct spring, every time… Easy as 1, 2, 3, iv.

Step i: Determine the Current of air Direction

Look at the end of the spring to determine the wind management. If the finish of the bound points in the clockwise management it is left-wound and if the cease of the spring points in the counter-clockwise direction, it is correct-wound. On most springs, current of air direction is also indicated by the color of the winding cones and cablevision drums — red indicates a right-wound spring while black indicates a left-wound spring.

Sometimes this pace tin can cause confusion. If you lot are not sure about your spring's current of air-direction, contact our squad today, and we would be happy to assist you.

Step ii: Mensurate the Wire Size

Measure out the length of 10 or twenty coils of the spring that needs to be replaced, using inches. Then compare that measurement to the garage door torsion spring chart beneath to decide the correct wire size.

| Length of 10 coils (in Inches) | Length of xx Coils (in Inches) | Wire Size |

|---|---|---|

| ane one/iv | ii one/2 | .125 |

| 1 3/eight | two 3/4 | .135 |

| one seven/16 | 2 7/viii | .142 |

| 1 1/2 | three | .148 |

| one 9/16 | 3 1/eight | .156 |

| 1 5/8 | 3 1/4 | .162 |

| 1 1/16 | iii 3/viii | .170 |

| ane 3/4 | 3 ane/two | .177 |

| 1 7/eight | 3 3/4 | .187 |

| i fifteen/16 | 3 7/8 | .192 |

| 2 1/16 | 4 1/8 | .207 |

| 2 3/xvi | 4 3/8 | .218 |

| 2 ane/4 | 4 1/2 | .225 |

| 2 5/sixteen | 4 five/eight | .234 |

| 2 7/16 | iv seven/8 | .243 |

| 2 1/2 | 5 | .250 |

| ii five/8 | v 1/4 | .262 |

| 2 3/4 | 5 one/two | .273 |

| two 13/sixteen | five 5/8 | .283 |

| two vii/8 | 5 3/4 | .289 |

| 2 fifteen/16 | 5 7/viii | .295 |

| iii 1/xvi | 6 1/viii | .306 |

| 3 1/8 | 6 ane/4 | .312 |

| three 3/16 | vi 3/viii | .319 |

| 3 5/16 | half dozen 5/eight | .331 |

| three seven/16 | 6 seven/eight | .343 |

| three five/8 | seven 1/viii | .362 |

| 3 3/4 | seven 1/2 | .375 |

| 3 15/16 | seven 7/8 | .393 |

| 4 i/16 | 8 1/8 | .406 |

| iv vii/32 | viii 7/sixteen | .421 |

| 4 five/xvi | eight v/8 | .430 |

| 4 3/eight | 8 3/4 | .437 |

| four 17/32 | 9 1/sixteen | .453 |

| 4 xi/16 | ix 3/viii | .468 |

| four 7/viii | ix iii/4 | .490 |

| 5 | ten | .500 |

| 5 five/16 | ten v/8 | .531 |

| five 5/8 | 11 i/4 | .562 |

| six 1/4 | 12 1/2 | .625 |

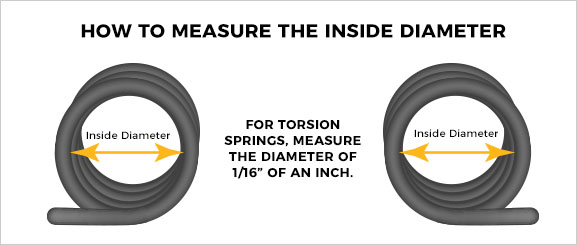

Pace 3: Measure the Within Bore

For torsion springs, measure out the inside bore to the 1/xvi" of an inch.

Step 4: Measure the Overall Length

Measure the overall length of the spring to the nearest quarter inch.

For any additional questions, explore the balance of the in-depth guide beneath, or contact our squad today.

contact usOrder Springs Here

In-Depth Guide: How to Measure and Order Replacement Torsion Springs: Everything Yous Demand to Know

- How to Determine Wind Management >>

- How to Determine Wire Size >>

- How to Measure the Within Bore >>

- How to Measure Overall Length >>

- Data to Have To Order New Springs >>

For pretty much anyone who owns an automatic garage door, garage door springs are a vital office of daily life. Anywhere from two to four times each 24-hour interval, the garage door is activated when heading to and from work, the supermarket or places of leisure. As such, the mechanical parts that activate a garage door are among the most utilized pieces of equipment in a typical household. Consequently, garage torsion springs can wear out during the average length of a residential occupancy.

The overhead torsion jump set is the part of a garage door system that allows the door to move up, downwardly and remain suspended at certain heights. With each activation, the coils are pulled out and wound dorsum upward. While torsion springs are made to endure such activity, over time the furnishings of the constant move can have their toll on the spring wire. Somewhen, the springs need to exist adapted or even changed out entirely.

How to Determine the Current of air Direction of a Garage Torsion Leap

Before you contact a garage door torsion jump manufacturer, it's important to know the direction in which a bound is wound. That way, y'all'll know whether you demand to replace a left-wound spring, a right-wound spring or both. In some cases, you might find that when ane garage door torsion spring is cleaved — be it the left-wound or the right-wound — the other will be nearing the stop of its life cycle every bit well.

How to Determine

Out of all the data you lot'll need to assemble before ordering garage door torsion springs, the easiest to determine is the air current of a given bound. Basically, the order of the springs from left to right should tell you everything you need to know.

From the inside of your garage, you'll likely see two springs forth opposite sides of a bar that hangs above the garage door. On most residential doors, the two springs are divided by a stationary cone. Though this might seem confusing at start, the left-wound spring is located to the correct of the cone, while the correct-wound spring is located to the left. The exception to this rule is when you're dealing with a garage door that uses a reverse torsion organization.

In most cases, right-wound and left-wound springs are further distinguished by demarcation colors along the winding cones and cable drums located at the far end of each leap. For the right-wound spring, the cone and drum is colored red. For the left-wound leap, the two parts are colored black.

Why Does This Matter?

It's important to know the direction of each torsion spring considering this is integral to the operation of the garage door. To make the door raise, each spring must turn in a certain direction. Likewise, the springs need to turn a certain way for the door to lower safely and steadily to the ground. If a wrong-turning torsion spring is applied on either side, the door just won't function properly.

When you contact an overhead door torsion spring manufacturer to request replacements, be sure to include info nearly the air current direction of the spring or gear up of springs you lot intend to supervene upon. Note the side of the bar on which the spring appears, as well as the colour along the end parts.

contact united states of america request a quote

How to Determine the Wire Size on Torsion Springs

When you lot measure a garage door jump, it's not enough to simply have a tape measure and record the length from one end to the other. You also demand to know the size of the wire itself. While this might seem hard to comprehend, measuring the wire size is actually equally easy every bit running a tape measure along the altitude between ten and 20 coils. The two measurements are then correlated to a wire size chart.

A lot of people would assume that wire size would more accurately be adamant with the employ of calipers or micrometers, but this is non the example. For instance, if a coil has a kink, a micrometer volition give you lot an inaccurate reading. Likewise, if the coils are coated with paint forth the exterior, information technology could cause a slight swelling in the circumference of the bound, which would also return a caliper measurement inaccurate.

Garage Door Torsion Spring Size Chart

| Length of ten coils (in Inches) | Length of 20 Coils (in Inches) | Wire Size |

|---|---|---|

| 1 1/4 | 2 ane/two | .125 |

| 1 3/viii | 2 3/4 | .135 |

| 1 7/16 | ii 7/8 | .142 |

| 1 1/2 | 3 | .148 |

| 1 9/xvi | three one/viii | .156 |

| 1 5/viii | 3 1/four | .162 |

| ane 1/16 | 3 three/8 | .170 |

| one 3/four | three one/two | .177 |

| ane vii/eight | iii iii/4 | .187 |

| 1 fifteen/16 | 3 7/8 | .192 |

| 2 ane/16 | 4 1/8 | .207 |

| 2 3/sixteen | four 3/viii | .218 |

| two one/4 | iv 1/2 | .225 |

| ii 5/16 | 4 five/8 | .234 |

| 2 seven/sixteen | four 7/8 | .243 |

| 2 1/two | 5 | .250 |

| 2 5/8 | 5 one/4 | .262 |

| 2 three/4 | 5 1/2 | .273 |

| 2 xiii/xvi | 5 5/8 | .283 |

| two vii/8 | 5 three/4 | .289 |

| 2 15/16 | 5 7/8 | .295 |

| 3 1/16 | 6 1/viii | .306 |

| 3 1/viii | 6 i/4 | .312 |

| 3 3/16 | six iii/8 | .319 |

| 3 5/xvi | six 5/8 | .331 |

| three 7/16 | 6 7/8 | .343 |

| three v/8 | seven 1/8 | .362 |

| 3 3/4 | seven ane/2 | .375 |

| 3 15/xvi | 7 7/viii | .393 |

| 4 i/xvi | eight 1/8 | .406 |

| iv 7/32 | 8 seven/xvi | .421 |

| 4 5/16 | viii 5/8 | .430 |

| 4 three/8 | 8 3/4 | .437 |

| four 17/32 | 9 ane/16 | .453 |

| four 11/16 | 9 iii/8 | .468 |

| 4 vii/8 | nine 3/4 | .490 |

| 5 | ten | .500 |

| 5 5/16 | ten five/viii | .531 |

| 5 5/8 | xi one/four | .562 |

| 6 ane/4 | 12 1/two | .625 |

How to Measure If the Spring Is Intact

If you're replacing a garage door torsion leap that's faulty however intact, it's relatively piece of cake to determine the wire size. First, you'll desire to lay the spring down on a table and pull out three scraps of paper. Place one fleck between two random coils, and so place a 2nd fleck exactly ten coils down the bound. Measure the altitude betwixt the two scraps of paper. Then, place the third bit exactly ten coils downward from the second, and measure the length from beginning to third scrap, between the 20 coils.

Next, have the 10-ringlet and 20-curl measurements, and see how they correlate on the wire size nautical chart in a higher place. For example, you might get measurements of 1 1/four inches betwixt the first 10 coils and two.v inches between all 20 coils. These numbers will likely correlate to ane of the sizes on your manufacturer's wire chart. If non, round things off to the nearest 16th of an inch.

How to Measure If the Jump Is Broken

When you need to replace a broken overhead door torsion leap, the job of measuring can be a bit trickier. Once again, y'all'll need to fix things down on a table and pull upwards 3 scraps of newspaper. If i of the spring halves is long enough, you lot can probably mensurate both the x-scroll and 20-whorl lengths on that half. Follow the same steps every bit you would with an intact spring: Place three scraps at x-roll intervals — y'all'll have a scrap at coil 1, 10 and 20. Measure out distances between the first and 2nd bit also as between the offset and third chip.

On the other hand, yous might demand to pull both halves of the spring together to become an accurate measurement of the ii lengths. For instance, on EZ-Set springs, gaps exist between the coils. Therefore, you're unlikely to go a 20-gyre measurement from one one-half of a broken spring. In a situation like this, you'll want to identify the outset ii scraps on whichever side contains 10 coils, then pull it together with the other half. Then, place the third bit at the 20th scroll and measure out both distances.

Other Wire Size Information to Know

Wire size can be hard to determine on rusty coils, which could throw off measurements taken past a caliper or micrometer. The main problem hither is that rust can crusade wires to aggrandize and and so shrink, which results in an altered size from anything on the size chart of the average garage torsion springs manufacturer. When corrosion does occur, withal, it tends to be along the outside, rather than in between the winding coils. Therefore, the newspaper-fleck measuring technique really is the most foolproof method for measuring wire size.

As a standard act of precaution, no coils should be touched while the torsion jump is even so on the bars in a higher place your garage door. Safely remove the spring or bound halves that need to exist replaced, and practise all handling on a apartment surface. Also, don't straight bear upon the set screws or whatsoever of the bolts to the stationary cone.

contact the states request a quote

How to Measure the Inside Diameter (ID) of a Torsion Spring

Earlier you lot contact an overhead door torsion spring manufacturer for replacement springs, yous'll need to know the diameter of the springs that currently need to be replaced. On many garage door bound sets, this is the easiest job of all, considering you oftentimes don't accept to brand any measurements. If you cheque the winding or stationary cone, you might see a number like 1.75 or 2.0. In the case of the former, the bound would have a i 3/4-inch diameter. With the latter, the bound would have a 2-inch diameter.

If no such number appears to be listed on the spring components, you'll need to take a uncomplicated measurement by paw. With the spring placed downwards on a apartment surface, run a ruler or measuring tape along the inside bore of the spring. The resulting measurement is the diameter of the jump. For example, if the ruler reads 1 3/iv″ across the hole within the coils, the wire has a diameter of 1 3/iv inches.

How to Mensurate the Overall Length of a Torsion Spring

The most of import measurement of all on a torsion jump is the overall length from 1 end to the other. The length of a torsion spring is integral to its winding chapters. If you have a big garage door, for example, you tin can't have an undersized jump and expect to get the needed lifting and lowering power. Simply put, torsion spring length is one of the cardinal aspects to the unique power of automated garage doors.

The task of measuring the length of a torsion spring is perhaps the easiest of all the tasks discussed here, because it involves no special tricks or unique understandings. Basically, yous run a record mensurate along the length of a spring, and take downward the number of inches. Therefore, if your tape measure indicates that a torsion leap is 36 inches from one end to the other, that's a 36-inch — or 3 foot — torsion spring.

How to Measure If the Bound Is Intact

If yous have a torsion jump that's intact yet faulty, lay it downward on a table and run a record measure from i finish to the other. Outset at the first coil on one end and extend the measuring device to the last curl. Don't include the end cone itself, but practice include whatever coils contained with the cone. Write downwards the number of inches and provide this information to a trusty garage door torsion spring manufacturer.

How to Measure If the Bound Is Broken

When a garage door torsion bound breaks in half, both parts must be pulled together on a apartment surface to get a proper measurement of the length. Simply place the two broken ends into place with ane another, then pull a tape measure out across the full length. If you have trouble belongings the spring halves together during this task, shove 1 of the far ends of the leap confronting a wall while running the tape measure out.

Some homeowners wonder why it'southward non appropriate to measure the individual lengths of partial springs and add the full measurements together. While information technology might seem like an easier method, you could actually end up more confused — or with an inaccurate sum — by trying to add fractional measurements together. There could always be a quarter–inch that's missed in one of the measurements, or a faulty measurement of the coil length at the points where the wire has broken.

Other Length Data to Know

Torsion springs cannot exist measured while agile. When a garage door is in move, for instance, each leap grows by a unmarried coil in length for every turn. Therefore, a leap on an open garage door — even if just partially open — volition not lend itself to authentic measurements.

Information to Have on Hand When Ordering New Springs

When y'all contact a garage door torsion spring manufacturer to social club new springs, it's important to have all the accurate info on mitt to ensure your new springs will match the ones needing to be replaced.

Data Needed:

- Length

- Inside Bore

- Wire Size

- Wind Direction

Order Springs Hither

You need to have proper measurements of the length, diameter, wire size and current of air management of each spring that needs to exist changed out. That manner, the torsion spring sales representative can assist you in finding springs that volition perfectly fit your garage door system.

Get New Garage Torsion Springs From IDC Jump

In the time you occupy a given household, you're bound to need repairs at some indicate to the mechanisms of your garage door. Whether you need to replace the left spring, right jump or both, information technology'due south important to know how to get together useful information and then yous tin can notice the right replacements. Even if you lot've never handled tasks like this before, the learning feel tin be invaluable considering it prepares you for bug that might ascend in the future with your garage door torsion system.

At IDC Bound, we assistance occupants of residential and commercial backdrop detect suitable torsion springs for garages of diverse sizes. Our commitment to client satisfaction has been recognized by 17 of the top 25 manufacturers in the garage door industry, who now use usa as their vendor. To larn more about what we can offer for your garage door, take a expect at our torsion springs product pages and contact us today.

contact u.s.a. request a quote

What Size Torsion Spring For 16x7 Garage Door,

Source: https://idcspring.com/measure-order-torsion-springs/

Posted by: josephboung1960.blogspot.com

0 Response to "What Size Torsion Spring For 16x7 Garage Door"

Post a Comment